Getting your first CNC router can be an exciting and intimidating experience. As a beginner, it's crucial to take the first 30 days as a learning period. During this time, you’ll become familiar with your machine, understand basic operation, create your first few projects, and learn how to maintain your machine. Whether you’re a hobbyist, maker, or small business owner, mastering these first steps is the foundation for success. This guide will walk you through the process of getting started with your CNC router, covering setup, operation, troubleshooting, and creating your first projects. With patience and practice, you’ll be able to unlock the full potential of your machine.

Setting Up Your CNC Router

The first step in your CNC router journey is the setup. While unboxing and assembling your CNC router may seem daunting, it’s a simple process that you can handle with careful attention to detail.

Unboxing and Assembly

Start by carefully unboxing your CNC router, and make sure to check for any visible damage during shipping. The user manual will guide you through the assembly process, but here are a few general tips:

- Organize Parts: Lay out all the components to ensure nothing is missing.

- Frame Assembly: Start by assembling the frame. Typically, CNC routers are modular and easy to put together, but make sure each part is securely connected.

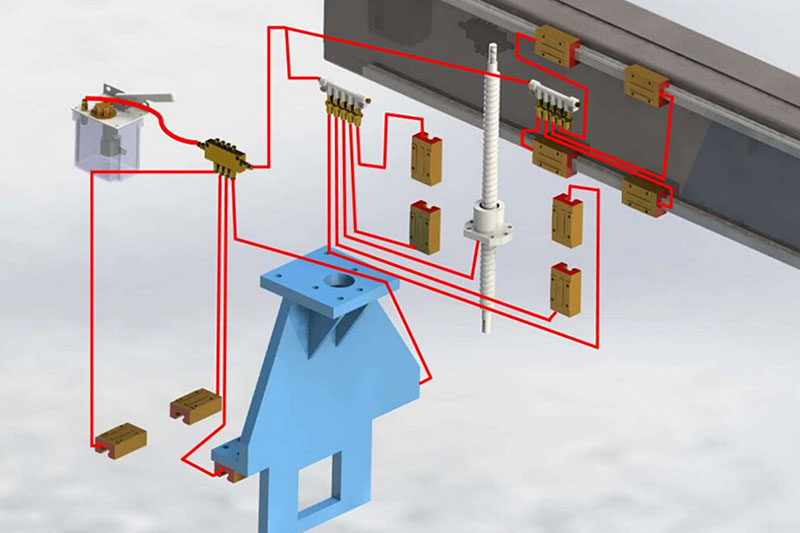

- Check Motors and Wiring: Ensure the motors are properly connected and wired. This includes the stepper motors, limit switches, and wiring for your controller.

Key Components to Check

Before powering up your machine, make sure all parts are in place:

- Controller: This is the brain of the CNC router. Double-check all wiring to the controller.

- Power Supply: Ensure your power supply is correctly installed and that voltage settings match your location’s power specifications.

- Cutting Tools and Collets: Verify that the right cutting tools are inserted into the collets, and ensure they’re secure.

Software Installation

Most CNC routers come with recommended software, which is used to design your projects and control the router’s movements. Popular software options for beginners include Easel, VCarve, and Fusion 360. Here’s what you need to do:

- Install the Software: Follow the installation steps provided in the manual. Ensure your computer meets the system requirements.

- Connect Your CNC Router: Once installed, connect the CNC router to your computer via USB or Ethernet, depending on your router model.

Learning the Basics of CNC Operation

Now that your CNC router is set up, it’s time to familiarize yourself with its operation. Learning how to control your machine is crucial before jumping into cutting.

Basic CNC Terminology

Understanding the lingo used in CNC routing will help you better operate your machine:

- Axes (X, Y, Z): These refer to the movement of your cutting tool. The X and Y axes control the horizontal and lateral movements, while the Z axis controls the vertical movement.

- G-code: The language used to tell the CNC router where to move, how fast to go, and how deep to cut.

- Feed Rate: This refers to how quickly the cutting tool moves through the material. Slower speeds are used for harder materials, while faster speeds work for softer materials.

- Stepper Motors: These motors are responsible for moving the CNC router along the X, Y, and Z axes.

Control Panel and Features

Next, take time to explore your CNC router’s control panel. This panel is where you’ll send commands and set parameters like speed, cutting depth, and tool offsets. Familiarize yourself with the following:

- Start/Stop Buttons: Learn how to begin and stop the machine’s operation safely.

- Jogging: This is the manual movement of the cutting tool along the axes to get it into position before starting a cut.

- Zeroing: The process of setting the home position for the router. Zeroing helps ensure the tool starts at the correct point on your material.

First Run: Test Cuts

Before cutting anything complex, perform a test run. Load a simple file and have the CNC router perform a dry run. This step will check for any mechanical errors, like incorrect motor movements or uncalibrated axes.

Your First 3 Projects

Creating your first few projects will help you develop confidence in your machine. Start with easy-to-make projects that will teach you the basics of CNC routing.

Choosing Simple Projects

For your first projects, stick to small, manageable designs:

- Coasters: A classic beginner project. Choose a simple design like your initials or a basic shape.

- Nameplates: Create a custom nameplate with simple text or basic vector shapes.

- Wooden Keychains: Small pieces like keychains are excellent practice because they don’t waste too much material.

Designing Your Project

Use CAD software to create your designs. If you’re new to CAD, start with easy-to-learn software like Easel, which allows you to design and control the router from the same platform. For more advanced users, Fusion 360 offers a broader range of design tools.

Setting Up Your CNC Router for the First Cut

Now, set up the material on your work surface:

- Secure the Material: Use clamps to hold your workpiece in place, ensuring it won’t move during the cut.

- Choose the Right Bit: Select an appropriate bit for the material you're using (wood, plastic, or metal). For soft woods, a straight-cut bit works well.

- Test Cut: Perform a dry run to ensure the design works as expected, then make your first cut.

Photo Credit: Elephant CNC

CNC Router Maintenance and Care

Proper maintenance ensures your machine runs smoothly for years. Regular checks and cleaning will keep your CNC router in top shape.

Daily Maintenance

- Clean the Machine: After each use, wipe down the machine and remove any wood dust or debris that could affect its performance.

- Check the Tooling: Inspect your cutting tools for wear and tear. Dull bits can cause uneven cuts and excessive wear on the machine.

- Lubricate: Keep the rails and moving parts lubricated to reduce friction and ensure smooth movement.

Weekly Maintenance

- Check Calibration: Verify that all axes are properly calibrated. Recalibrate if needed to avoid issues like misalignment during cuts.

- Tighten Components: Tighten screws, bolts, and nuts, particularly those on the frame and motors, to prevent any loosening over time.

Troubleshooting Common Issues

CNC routers, like any machine, can run into problems. Here are common issues and how to resolve them:

Calibration Problems

If your machine isn’t cutting accurately, you may need to recalibrate it. Recheck the machine’s home position and verify that the axes are aligned correctly. This ensures your router is cutting where you intend.

Uneven Cuts

Uneven cuts often result from an incorrect feed rate or a dull bit. Adjust your feed rate based on the material you’re using, and if necessary, replace your bit.

Software Errors

Software errors can cause the CNC router to malfunction. Ensure that your software is up to date and compatible with your router. Double-check the G-code file for any errors before running the machine.

Photo Credit: Dan Lee Boat Building

How to Continue Learning

After the first 30 days, you’ll feel more confident with your CNC router. Here are a few ways to continue improving:

- Online Courses: There are many free and paid courses available to deepen your CNC knowledge.

- Community Forums: Join online forums like CNCZone or Reddit’s CNC community to learn from others and share your experiences.

- Advanced Projects: As you grow more comfortable, tackle more complex projects like 3D carvings, furniture, or even functional parts for small machines.

Your Journey Starts Here

Have you completed your first 30 days with your CNC router? Share your experiences in the comments below, and let us know what projects you’re planning to tackle next. Don’t forget to subscribe to our newsletter for more beginner tips and project ideas!